Volunteers at Nissan’s Sunderland car factory have set up a parts processing line to help distribute personal protective equipment to the NHS.

Almost 80,000 face visors will be distributed to frontline workers this week, rising to 100,000 a week from next week.

The project was inspired by two brothers working at the Nissan Technical Centre in Cranfield.

ALSO READ: NHS workers to get free Uber rides

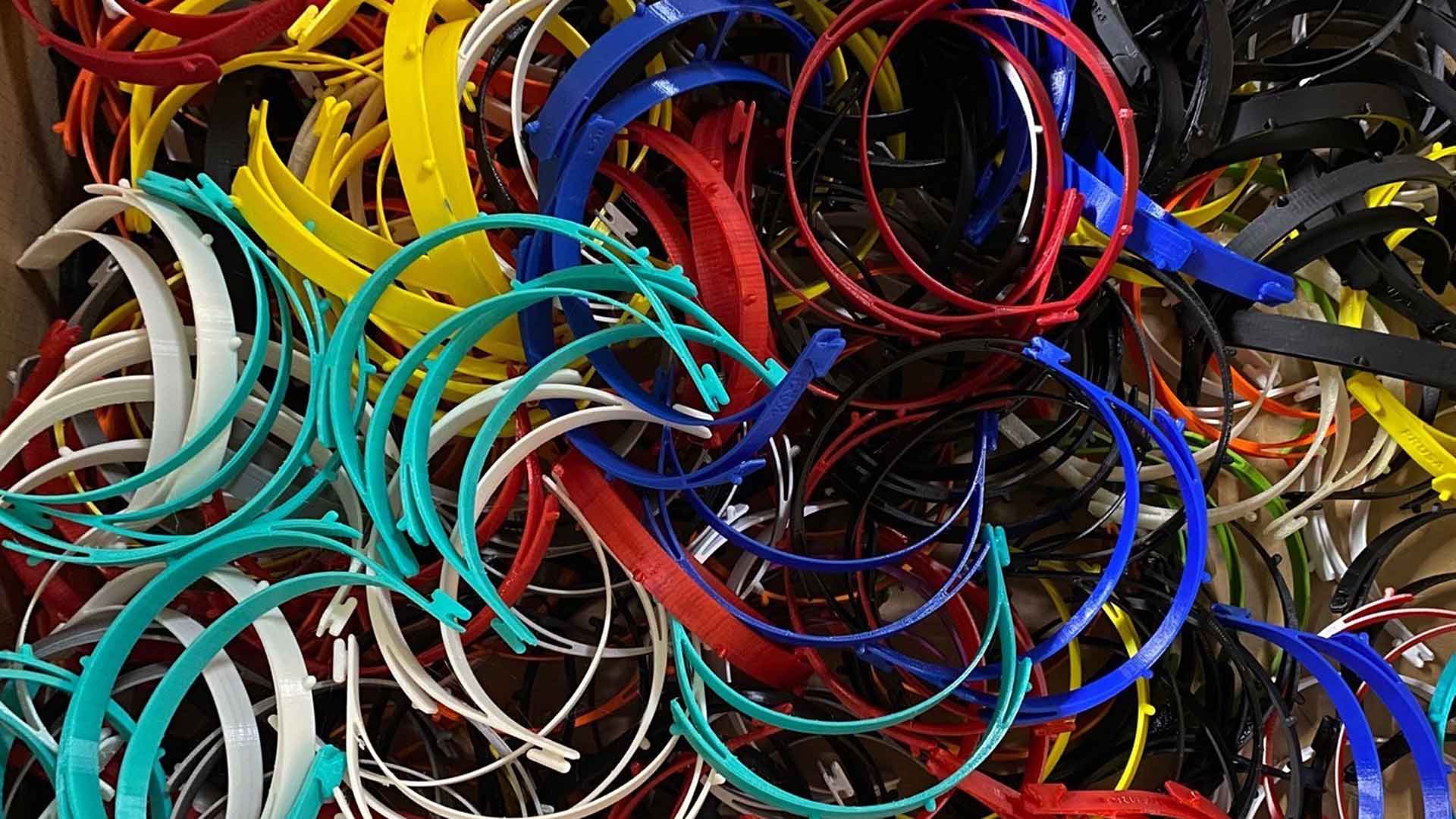

They were among hundreds of people in the UK who have been making PPE using their 3D printers. Supplies were purchased using crowd-funded donations.

Hundreds of boxes of volunteer-produced visor parts have now been delivered to Nissan Sunderland. The experts there have worked on the logistics to create an efficient PPE supply chain.

One of the brothers, Anthony Grillis, said: “We had the ability to support the national effort to produce more PPE for frontline health workers and we just had to help.

“We quickly mobilised to produce parts using our 3D printing capability at home and we’re grateful to everyone that donated through our crowd funding site to help us get this going.”

Nissan has also stepped in to fund an injection-moulding tool, allowing a greater volume of parts to be produced.

The visors are made of three parts: an elastic headband, frame, and the see-through visor itself.

Nissan packs and distributes the visors to an NHS procurement centre in a ready-to-assemble format.

This helps minimise the risk of damage during transit, and ensure as many pieces of PPE can be dispatched at once.