The first Bentley has passed through the doors of the firm’s new Excellence Centre, opened to drive the “imperious quality” of every car the company builds.

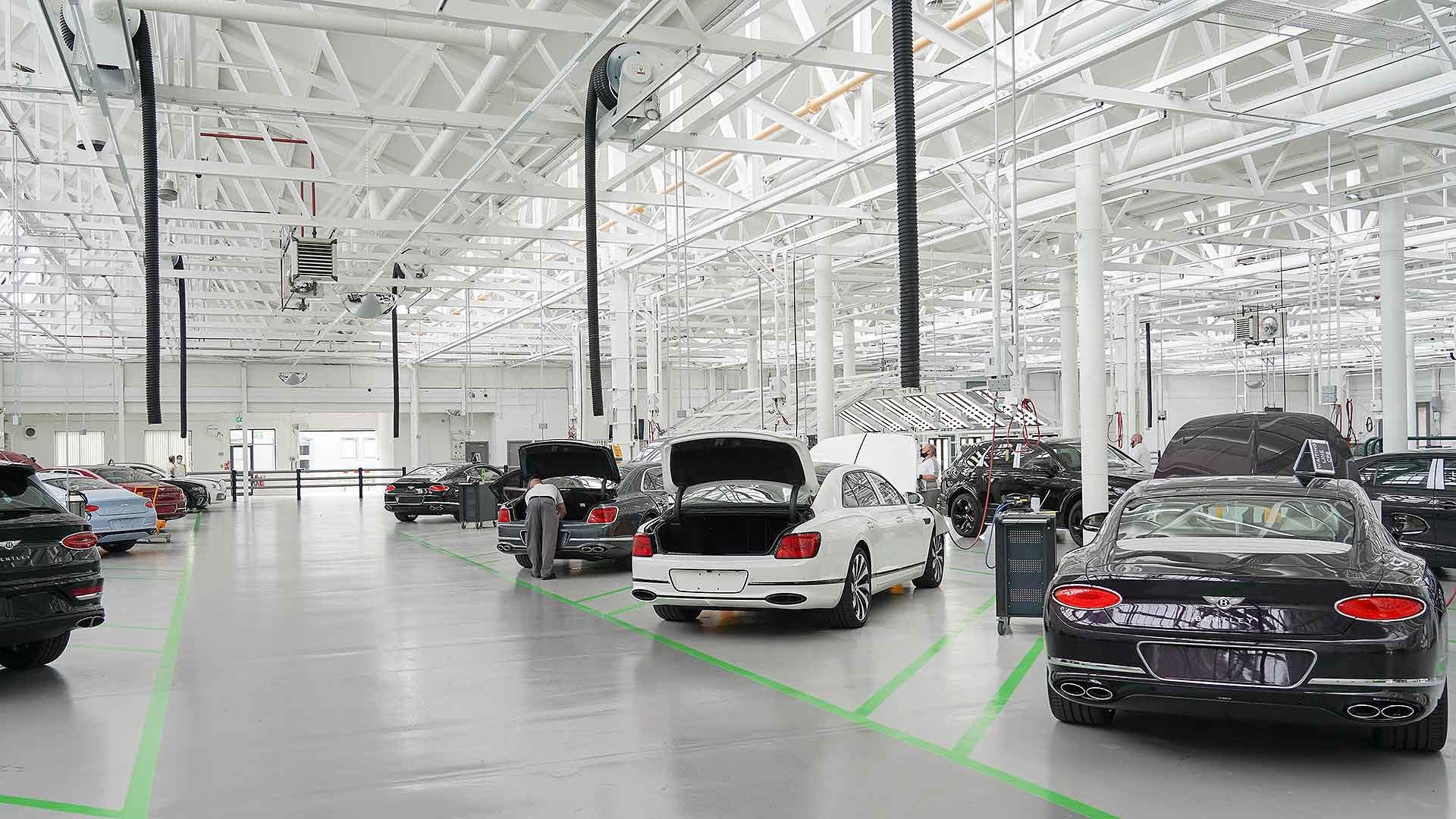

Housed in the former Mulsanne factory, the Bentley Excellence Centre is home to a team of 50 “hand-picked craftspeople”.

They will carry out a 650-point check of all new cars, which Bentley says guarantees “perfection” before each car is signed off.

The checklist takes two hours to complete – and, each week, 20 randomly-selected cars will undergo an even more comprehensive quality audit.

The first car, a Bentayga V8, was this week driven off the new line by manufacturing board member Peter Bosch.

“Every Bentley model has always been hand-built and checked to the very highest standards,” he said. “The new Excellence Centre for Vehicle Finish takes our meticulous standards even further.

“Colleagues wear white gloves to ensure that our hand-built cars leave the facility without so much as a fingerprint on.”

These skills are augmented by artificial intelligence “to ensure our current and future cars will continue to meet our customers’ high expectations”.

Bentley adds that its entire Crewe facility, already carbon neutral since 2018, is on track to become carbon positive by 2030.

ALSO READ

New Bentley steering wheel fits real AND virtual racers